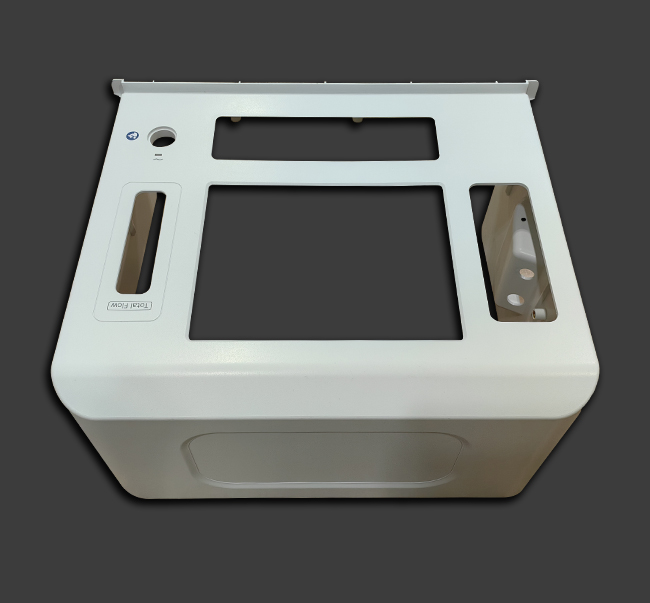

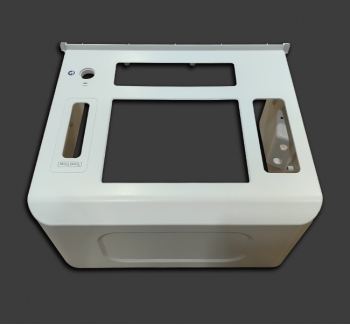

Medical equipment shell injection mold is used to produce medical equipment shell mold. Injection moulds are usually made of steel, and their design and manufacture need to consider factors such as the shape, size, accuracy requirements, material characteristics, and process requirements for injection molding production.

When making an injection mold for a medical device housing, the following steps are generally required:

1, design: According to the design requirements of the medical equipment shell, the mold structure design, including cavity, core, pouring system, cooling system, etc.

2, material selection: select the appropriate mold steel material to ensure the strength, wear resistance and service life of the mold.

3, processing: through mechanical processing (such as milling, grinding, drilling, etc.) to manufacture the various parts of the mold.

4, assembly: the processed parts are assembled to ensure the accuracy and coordination of the mold.

5, test mold: trial production, check the performance of the mold and the shell produced to meet the requirements, may need to adjust and optimize the mold.

6. Mass production: After successful trial, mass production can be carried out.