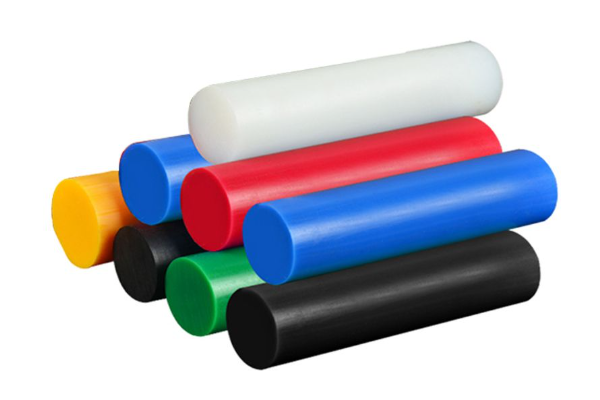

Advantages and disadvantages of UHMWPE ultra-high molecular weight polyethylene

UHMW Ultra-high molecular weight polyethylene (UHMWPE) is a thermoplastic polymer with very high molecular weight.

The molecular weight of UHMWPE is generally in the range of millions to tens of millions of grams per mole. It has many

advantages, but also some potential disadvantages. Here are some of the main advantages and disadvantages of UHMWPE:

Advantages:

Extremely high wear resistance: UHMWPE has excellent wear resistance, which is one of its most striking characteristics.

This makes the material suitable for applications that require extremely low friction.

High impact resistance: UHMWPE shows excellent impact resistance at room temperature and even at low temperatures.

Low coefficient of friction: Compared to metal and other plastic materials, UHMWPE has a very low coefficient of friction,

which reduces energy consumption and wear between contact surfaces.

Excellent chemical resistance: UHMWPE is highly resistant to most organic solvents, oils and chemicals.

Good corrosion resistance: it is not easily affected by corrosion, making it suitable for harmful environments.

Low water absorption: UHMWPE absorbs almost no water, which means its performance is almost unaffected by humidity.

Non-adhesive surface: UHMWPE surface does not easily stick to substances.

Odorless, non-toxic: usually suitable for contact with food environment.

Cons:

High coefficient of thermal expansion: UHMWPE has a large coefficient of thermal expansion, which may lead to poor dimensional

stability in environments with large temperature differences.

Not suitable for processing: Due to its extremely high molecular weight, the processing of UHMWPE is more difficult, and

conventional plastic molding technology is more difficult.

Low temperature use restrictions: Although UHMWPE can be used at low temperatures, its maximum use temperature is

usually limited to about 80°C to 100°C.

Ultraviolet (UV) sensitivity: UHMWPE may degrade and become brittle if exposed to prolonged sunlight.

Difficult to bond: Due to its non-adhesive surface characteristics, UHMWPE is difficult to bond with other materials.

Despite these shortcomings, UHMWPE is widely used in many fields such as mechanical parts, food industry, medical devices,

textile machinery, snowboard undersides, etc., due to its excellent performance characteristics.